Is it possible to combine design, artisanal quality and innovation? The answer is affirmative, especially with regard to bathroom furnishings: the latest generation of materials have unleashed designers from the limits of traditional ceramic products, enabling the creation of bathroom fixtures of captivating design, with surfaces that are perfectly polished and cared for in every minute detail.

A perfect example of the possibilities offered by the use of innovative materials is the Mastella Design free standing sinks and tubs, created from the sketches of the designers who collaborate with the company: soft waves, thin petals and wrap-around spirals, born from the pencils of creative people, are transformed into products with fluid and organic forms, thanks to extremely ductile materials such as Cristalplant, capable of assuming any form by means of cast moulding or low pressure stamping.

The various stages from which Mastella Design products originate follow a path that embraces high level artistic, manual and technical skills.

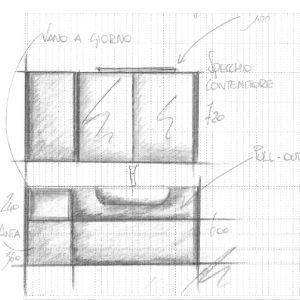

It starts with the initial sketch, from which a 3D drawing is obtained which is used to create the full-scale prototype. At this stage, the designer consults with the technicians to verify that the thicknesses are appropriate for the material’s machining specifications and that the piece does not exhibit excessive undercuts.

Once the prototype has been developed, it is possible to move on to the next step, namely to create the mould, which is subsequently inserted into a special moulding press composed of various parts which, when finished, are opened and separated to allow the extraction of the piece.

Cristalplant is injected in liquid form into the mould cavity, left to catalyze and then solidify in all its parts for as long as necessary.

At this point, the surface finishing phase begins, which is done manually with special sand papers and scouring pads: this treatment is designed to obtain the particular velvety, warm and soft touch effect that characterizes this material.

Finally, the product is subjected to various quality assurance checks, such as tests using abrasive detergents and sponges to clean stains.

The end result of this process is a velvety, non-porous, fitting-free product, able to meet the highest functional, constructive and hygienic standards, while at the same time ensuring maximum comfort and a design that is refined and contemporary.